Call Us Now

08045801618- Home Page

- Company Profile

-

Our Products

- Boats

- Secu 13 Polyethylene/Funyak 390 PE/ HDPE Boat/ Life Boat/ Motor Boat/Rescue Boat/ Speed Boat/ 6 to 8 Seater Boat/ GSDRF Specification/6 to 8 people Boat/6 to 8 passenger Boat/6 to 8 person Boat

- speed 10-12 seater pontoon boat, 10-12 seater party pontoon boat, 10-12 seater VIP pontoon boat/ 10-12 seater Leisure cruising pontoon boat,10-12 seater Tourism pontoon boat/oat

- Speed Boats

- 400 Polyethylene/ PE/ HDPE/ Life Boat/ Rescue Boat/ Motor Boat/ Speed Boat/ 6 to 8 Seater Boat/ 6 to 8 person Boat

- Jet Attack/Jet ski replacement/ fast speed boat/PE/ HDPE/ Life Boat/ Motor Boat/ Rescue Boat /Speed Boat/ 3 to 4 Seater Boat/ 3 to 4 people Boat/ 3 to 4 passenger Boat/ 3 to 4 person Boat/water scooter

- 570 Polyethylene/ PE/ HDPE/ Life Boat/ Motor Boat/Rescue Boat / Speed Boat/ 12 to 14 Seater Boat/ GSDRF Specification/12 to 14 person Boat/12 to 14 people Boat/12 to 14 passenger Boat/

- Family pedal boat/ Litmus pedal boat/ 4 to 5 seater pedal boat/4 to 5 person pedal boat /4 to 5 passenger pedal boat

- Mac -390 - Roc-ket Boat,HRocket Boat Polyethylene/ PE/ HDPE/ Life Boat/ Motor Boat/Rescue Boat/ Speed Boat/ 4 to 5 Seater Boat/4 to 5 people Boat/4 to 5 pasenger Boat/4 to 5 person Boat

- Donut Boat/Round boat/ touris boat/ round luxuey boat/ 4 to 5 seater round boat

- inflatable raft boat

- Fatcat 4000

- raft Inflatable raft Boat

- FRP Litmus 4.8 m Boat/ FRP indigeneous boat/ 6 person FRP boat/6 people FRP boat/ FRP 6 passenger boat

- 8 seater inflatable boat

- 4.2m Inflatable Boat

- Speed Boat

- Catamaran Boat, PE Catamaran Boat

- Rescue Boat

- PE Pedal boat/ 2 to 4 pedal boat/ paddle boat/ 4 person pedal boat/ 4 people paddle boat

- inflatable rigid boat

- Inflatable Boat

- Korkyra 650 Double Engine Catamaran Boat, PE Catamaran Boat, HDPE Catamaran Boat, HDPE Rescue boat, 10 Passenger Boat, 10 Seater boat, 10 People boat,

- Excursion Pontoon Boats

- 6 to 8 person/ 6 to 8 people/ Boat Boat/4200 Polyethylene/ PE/ HDPE/ Life Boat/ Motor Boat/ Rescue Boat/ Speed Boat/ 6 to 8 Seater Boat

- Funyak Secu 12/ PE Rescue boat / 5 to 6 Seater boat / 5 to 6 people boat /5 to 6 Pasenger boat /Secu 12

- 350 Polyethylene/ PE/ HDPE/ Life Boat/ Rescue Boat/ Motor Boat/ Speed Boat/ 5 to 6 Seater Boat/5 to 6 passenger Boat

- 450 Polyethylene/ PE/ HDPE/ Life Boat/ Motor Boat/ Rescue Boat/ Speed Boat/ 8 to 10 Seater Boat/8 to 10 passenger Boat/8 to 10 people Boat

- 8 to 10 Seater Boat / 8 to 10 passenger Boat/ 4800 Polyethylene/ PE/ HDPE/ Life Boat/Rescue Boat/ Motor Boat/ Speed Boat/

- 600 Polyethylene/ PE/ HDPE/ Life Boat/ Motor Boat/ Rescue Boat/ Speed Boat/ 10 to 12 Seater Boat/10 to 12 passenger Boat/10 to 12 person Boat/10 to 12 people Boat/tourist boat/

- 6 to 7 Seater Boat /Cataraman boat/4000 Catamaran/ Self Bailing/ Polyethylene/ PE/ HDPE/ Life Boat/ Motor Boat/Rescue Boat/ Speed Boat/ 6 to 7 Seater Boat

- 12 to 14 people Boat/cataraman boat/ 4500 Catamaran/ Self Bailing/ Polyethylene/ PE/ HDPE/Rescue Boat/ Life Boat/ Motor Boat/ Speed Boat/

- Parasail Boat/ Parasailing boat/ Fun boat/ Fun riding boat

- PE 2 seater pedal boat/ paddle boat/ pedal boat/ 2 person pedal boat/

- FRP White Indigeneous Safari Boat/ 12 Seater FRP boat/Safari Boat

- 10 seater inflatable boat

- HDPE Rescue boat, 12 Passenger Boat, 12 Seater boat, 12 People boat, 10 to 12 seater boat, Life boat for Rescue, Motor boat, PE rescue boat, PE boat, HDPE boat,

- 715 Family Cruise Pontoon Boat/ Family Pontoon boat/ cruise boat/cruize boat/Petrol Aluminium Apex Marine/ Petrol Family Pontoon boat

- 6 seater inflatable boat

- 450 Polyethylene/Secu 15/ PE boat / HDPE/ Life Boat/ Rescue Boat/ Motor Boat/ Speed Boat/ 8 to 10 Seater Boat/ 8 to 10 people Boat/ 8 to 10 person Boat/ 8 to 10 passenger Boat

- HDPE Rescue boat, 12 Passenger Boat, 12 Seater boat, 12 People boat, 10 to 12 to 14 seater boat, Life boat for Rescue, Motor boat, PE rescue boat, PE boat, HDPE boat

- Litmus Inflatable Rescue Barge/50 Passenger Inflatable Rescue Barge

- Donut Boat

- FRP Litmus speed boat/6 seater speed boat/ 6 seater luxury boat/ Six seater boat/ 6 person FRP boat/6 people FRP boat/ FRP 6 passenger boat/ 6 seater speed luxury boatLitmus speed boat

- 4.5m Inflatable Boat

- Sea Royal boat/ FRP boat / 5 to 6 seater frp boat

- 4.7m inflatable boat

- Inflatable Boats

- Electric Boats

- HDPE Speed Boat

- Speed Boats

- Rescue Boats

- MAC HDPE SPEED BOAT

- Speed Boat

- MAC HDPE SPEED BOAT

- Boats

- DINGHY 250 Boat

- DINGHY 350 Boat

- DINGHY 440 Boat

- 2 Seater Pedal Boat FRP

- 4 Seater Pedal boat FRP

- 6 Seater Pedal Boat FRP

- YAMAHA WAVERUNNER VX1050 JET SKI

- Pontoon boat

- Sailing Boat

- Water Bus

- Whaly Classic Boat

- Asis Amphibious Boat / patrollling boat/ navy boat/ search rescue boat/ rapid action boat/ armed force boat / security boat/ naval force boat / coastal guard boat / naval force boat

- Jet boat/ speed boat

- 7518 Cruise Deluxe Pontoon Boat/ Deluxe Family Pontoon boat/ deluxe cruise boat/deluxe cruize boat/luxrious cruise boat / Apex Marine Deluxe boat/Apex Marine luxrious boat

- 7522 Triple Pontoon Boat Triple Pontoon Boat Deluxe/ Triple Pontoon Family Boat / Triple Pontoon Boat luxrious cruise boat / Apex Marine Triple Pontoon Boat

- 616 Family Cruise Pedal Pontoon Boat/ Pedal Pontoon Boat/ Deluxe pedal pontoon / boat/ Luxrious pedal pontoon / boat/ Apex Marine Pedal pontoon Boat/

- 6 to 8 Persons, 6 to 8 Passenger , 6 to 8 Seater boat, 6 to 8 People boat, Life boat for Rescue,IRS rescue boat, IRS member Certified Boat,

- Catamaran Passenger Ferry 50 Pax/Catamaran Passenger boat/ 50 people Cataraman boat/50 person Cataraman boat,50 seater Cataraman boat/50 pax Cataraman boat

- Sea Royal 480/ FRP boat

- FRP Litmus 5.6 m Boat/ FRP 10 seater boat/ frp speed boat

- Sports Stuff Airhead Big Mable 2 seater towable / bumper / tube / ringo

- Sports Stuff Airhead Bandwagon 2 + 2 - 4 seater towable / bumper / tube / ringo

- HO Sports Formula 2 seater towable / bumper / tube / ringo

- Airhead High Roller 4 seater Towable / bumper / tube / ringo / sleeping bumper

- Explorer 14.6 DLX Canoe/2 seater canoe/ Pelican Canoe

- Pelican Green Export 15.5 Canoe, 2 to 3 seater canoe

- Polyethylene Multicolor Voyager Tandem 2 Seater Sit On Top Kayak/ Indian 2 seater kayak/ Yolo 2 seater kayak/ Yolo kayak 2 person

- YOLO Katch Single Seater Sit On Top Pro Fishing Pedal Kayak/ single person kayak/

- Litmus Water Bicycle 2 Person

- Sport Boats

- JEt Attack (Replacement of jetski)

- Electric Jet Ski

- Water Ski/ water sports/

- ExDeluxe 1050 Jet Ski / 2 seater Jetski / Yamaha 2 people jetski/ 2 to 3 people Jet ski

- Sport Boats

- Canoe Boat

- Rowing Boat

- Three Seater Boat

- RTM Sea View Board

- ExSport 1050 Jet Ski/ 2 to 3 seater Jetski/ Yamaha jetski

- Fun Ski Single Seater Sit On Top Kayak/yolo single seater kayak/ yolo kayak single person

- Litmus Water Bicycle Single Person/

- Litmus Adult & Kids Water Tricycle

- FRP Litmus speed boat/8 seater speed boat/ 8 seater luxury boat/ Eight seater boat/ 8 person FRP boat/8 people FRP boat/ FRP 8 passenger boat/ 8 seater speed luxury boat

- FRP Litmus speed boat/10 seater speed boat/ 10 seater luxury boat/ Ten seater boat/ 10 person FRP boat/10 people FRP boat/ FRP 10 passenger boat/ 10 seater speed luxury boat

- Kayak

- Sit on top kayak

- Kayak Boat

- Sit In kayak

- 2 Seater Kayak

- Sentinel 100X Single Seater Sit On Top Kayak/ single person kayak imported/

- River Gorge 130XP Tandem Sit On Top Kayak/ 2 seater kayak imported/ 2 person Kayak imported/ Tandem imported kayak/ sit on kayak 2

- Makao Single Seater Sit On Top Kayak/ kayak singler seater/ kayak imported /kayak single person

- Duetto Tandem Sit On Top Kayak/ seater 2 kayak/ kayak tandem

- Ocean Duo Tandem Sit On Top Kayak/ ocean 2 seater kayak/ tandem ocean kayak

- Ocean Quatro Tandem Sit On Top Kayak/ 2 to 3 seater ocean kayak/

- Riviera Canoe

- Polyethylene Blue RTM Riviera XL Canoe/PE CANOE

- Polyethylene Multicolor RTM SX 285 White Water Single Seater Kayak/ seater kayak one

- Marine Repair Services

- Inflatable Boat

- Scuba Diving Equipment

- Towables

- Litmus 12 seater flyisng fish bumper / towable / tube / ringo

- Sports Stuff Airhead Poprazzi 2 seater bumper / towable / ringo / tube/2 seater towable,2 person towable,2 people towable,2 passenger towable/ 2 seater Bumper

- Ocean Rider 6 Seater White Dolphin Boat / inflatable dolphin boat

- Airhead Strike 1 single seater towable / bumper / tube / ringo / sleeping type

- 6 seater flying fish bumper

- Sports Stuff Airhead Porazzi 3 seater towable / bumper / tube / ringo/3 seater towable,3 person towable,3 people towable,3 passenger towable/ 3 seater Bumper

- Raft Bumpers

- Bumper BO

- Sports Stuff Airhead Great BIg Mable 4 seater Towable / Bumper / Tube / Ringo/ 4 person towable/4 passenger towable/4 people towable/ Great Big mable

- Sports Stuff Airhead Super Mable 3 seater towable / bumper / tube / ringo

- Sports Stuff Airhead Chariot Warbird 3 seater towable / bumper / tube / ringo

- Sports Stuff Airhead Grandstand 2 seater towable / bumper / tube / ringo

- HO Sports Formula 3 seater towable / bumper / tube / ringo

- Airhead Blast 4 seater towable / bumper / tube / ringo

- Airhead Sea Monster 4 seater towable / bumper / tube / ringo

- Airhead Xcelerator 2 seater towable / bumper / tube / ringo

- 6 Seater Yellow Ocean Rider Banana Boat/ inflatable banana boat

- Ocean Rider 8 Seater Yellow Banana Boat/ inflatable banana boat

- Ocean Rider 8 Seater White Dolphin Boat/ Inflatable 8 seater dolphin

- Litmus 4 seater flying fish bumper / towable / tube / ringo/

- Fire Product

- Flood Light P25/FLOODLIGHT P25/ Rescue flood light/ emergency flood light

- rescue light

- ROLA LIGHT 30/LIGHT/Emergency Light/

- Motion Detector Gaurdangle

- TUB 4000 LIGHT/HANDHELD RESCUE LIGHT TUB4000/ Hand rescue light/

- Tub 4000 Modular Ambiant Autonomous Lighting

- AUTO INFLATING FOLDABLE REMOTE CONTROLLED RESCUE BOAT/ Remote operated rescue boat/ rescue boat remote operated/ resuce boat foldable remote operated/

- Marine Product

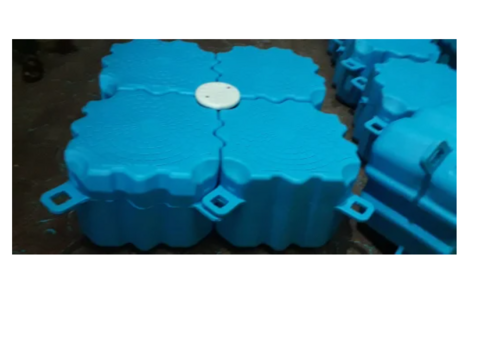

- u floaitng cube

- floating cover cube

- half floating cube

- Magic Float Horizontal Walkway Float for solar support

- Gangway for floating bridge

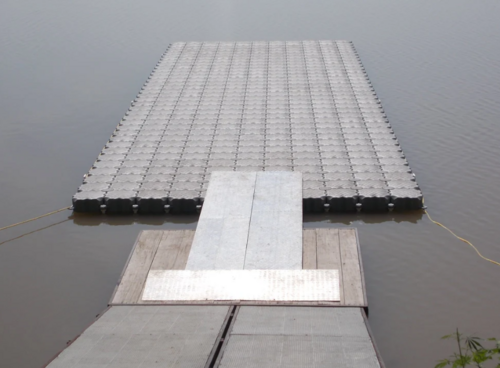

- 3 x 2 mtr floating docks

- Life Ring Buoy/Indian life ring/ Indian Life Buoy/

- Litmus Life Jacket/ Indian Life Jacket/Marine jacket

- Magic Float Vertical Walkway Float for solar support

- half floating cover cube

- floating docks

- HDPE floating cube

- barrier railing for jetty

- floating cubes

- rubber fender

- floating solar module

- HDPE FLOATING JETTY

- Remote Control Lifebuoy/ Remote Control Life/Remote control Life saving lifebuoy/ marine safety equipment/ remote operated Lifebuoy

- Hand Railings for Jetty

- River Rafting Helmet

- Life Jacket

- Rescue Tube

- Boat Paddle

- Imported Life Jacket/Red & Black Aropec Foam Life Jacket/ Aropec Life jacket

- EPE Foam Red & Black Aropec Neoprene Life Jacket, For Sea Patrolling/ Neoprene Life Jacket/

- Yellow Aropec Foam Kids Life Jacket, For Sea Patrolling/Kids Life Jacket/

- Red Aropec Life Ring Buoy, Round Imported Life Ring/ Imported Life Buoy/

- Aropec Rescue Tube/ Imported Rescue Tube/ Life saver Rescue Tube

- Aropec Diving Set/ Imported Diving suit/

- indian roller for piling jetty

- OBM Repairs and servicing

- OUTBOARD MOTORS

- Torqeedo Travel Ultralight Outboard Motor

- 2hp electrical engine/ temo engine/small electrical engine/ handy electrical engine/Temo 450 Electric Outboard Motor

- 50 HP diesel engine

- Torqeedo Cruise 10 Tiller Electric Outboard Motor,

- Tohatsu 2.5 HP to 140 HP OBM/ Petrol engine/ Petrol Outboard motor/ Petrol obm

- Torqeedo Ultralight 403 AC Electric Outboard Motor/ Electric engine for kayak, canoe torqeedo electric engine

- TEMO Outboard Engines

- TOHATSU OBM Outboard Engines

- TORQEEDO ELECTRICAL OBM OUTBOARD MOTORS

- Torqeedo Ultralight 1103 AC Electric Outboard Motor/ Torqeedo engine 1103 AC

- Torqeedo Travel S 3 HP Electric Outboard Motor/ 3 HP Electric / Torqeedo 3 HP

- Torqeedo Cruise 3 Tiller / Remote Electric Outboard Motor/

- Torqeedo Cruise 6 Tiller Remote Electric Outboard Motor

- Torqeedo Travel XP 5 HP Electric Outboard Motor

- Torqeedo Cruise 12 Remote Electric Outboard Motor

- Mercury 25 HP to 115 HP OBM Outboard Motor

- Molabo Aries R50 Outboard Motor (Electric OBM)

- Boats

- Contact Us